Features

- Meehanite Class FC30 casting with slide way provides high stiffness and wear resistance maintaining the accuracy of the machine.

- Spindle lateral design creates stability during heavy cutting.

- Spindle V3 Grade motor provides good water proofing resisting moisture.

- Vertical feeding uses 3 high stiffness and rigidity linear roller guides allowing smoothly vertical feeding whilst maintaining high stiffness.

- Small workpiece suction is accomplished by fine electrical magnetic chuck.

Specification

| Description | HR-400 | HR-500 | HR-600 |

| Rotary magnetic chuck dia. | 400mm | 500mm | 600mm |

| Max. grinding height | 225mm | 275mm | 325mm |

| Distance of table surface to spindle surface center | 450mm | 450mm | 450mm |

| Rotary magnetic chuck speed | 20~250r.p.m. | 10~150r.p.m. | 10~150r.p.m. |

| Rotary magnetic chuck horse power | 1.5kw | 2kw | 3kw |

| Spindle speed | 5HP | 5HP | 10HP |

| Spindle speed (50/60Hz) | 1450/1750r.p.m. | 1450/1750r.p.m. | 1450/1750r.p.m. |

| Auto down feed horse power | Servo Motor 500w | Servo Motor 500w | Servo Motor 500w |

| Vertical hand wheel down feed per revolution | x1, x5, x10(MPG)/0.1, 0.5, 1mm | x1, x5, x10(MPG)/0.1, 0.5, 1mm | x1, x5, x10(MPG)/0.1, 0.5, 1mm |

| Vertical hand wheel down feed per graduation | x1, x5, x10(MPG)/ 0.001, 0.005, 0.01mm | x1, x5, x10(MPG)/ 0.001, 0.005, 0.01mm | x1, x5, x10(MPG)/ 0.001, 0.005, 0.01mm |

| Wheel size (dia x width x bore) | 355x38x127mm | 355x38x127mm | 355x38x127mm |

| Net weight / gross weight (approx.) | 3200/3800kg | 3500/4000kg | 4600/5200kg |

| Packing size (LxWxH) | 2400x1900x2100mm | 2400x2100x2100mm | 2800x22000x2200mm |

※ The manufacturer reserves right to modify the design , specification mechanisms etc. without notice.

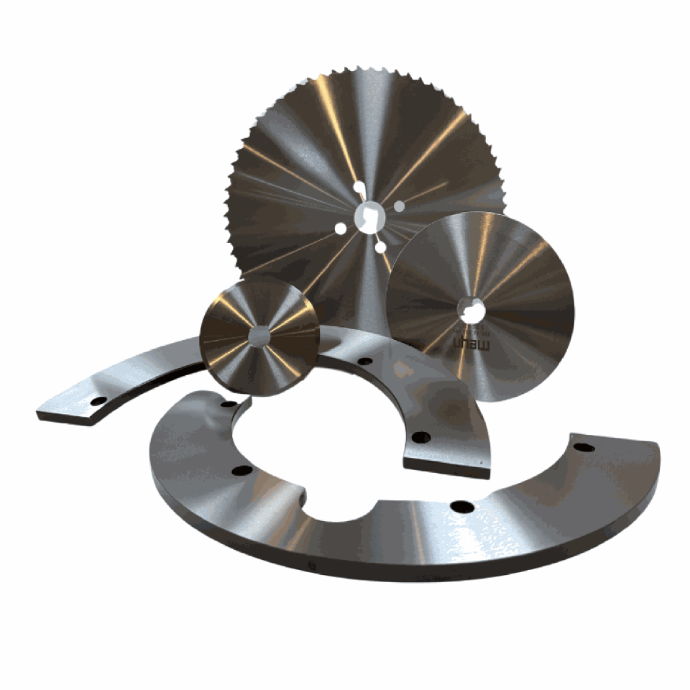

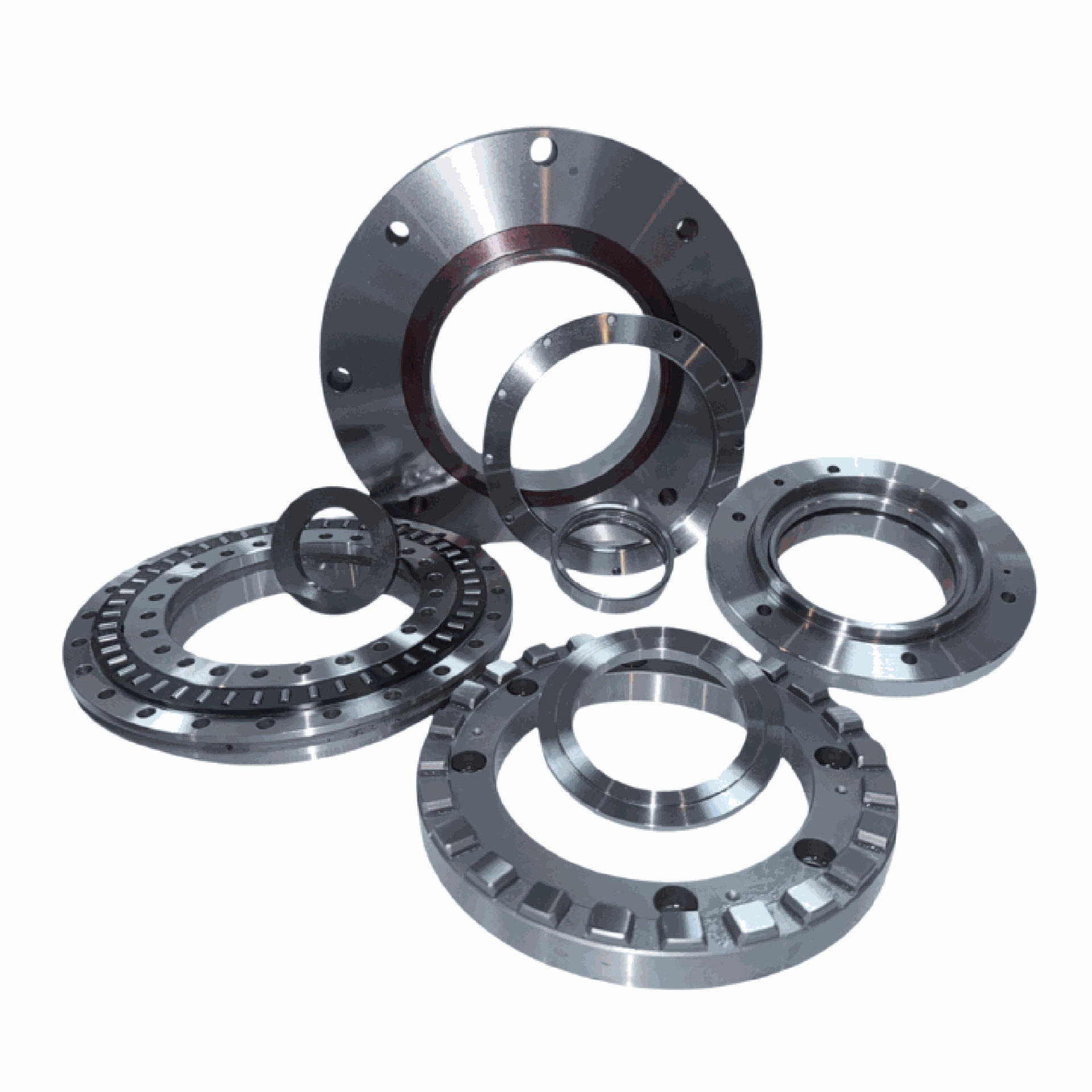

Workpiece Sample