Features

- Meehanite Class FC30 casting with slide way provides high stiffness and wear resistance maintaining the accuracy of the machine.

- Vertical Y axis uses Class 1 ball screw Ø50 provides high stability during feeding.

- Vertical and longitudinal feeding uses high stiffness and rigidity linear roller guides made in Japan (slide block x6) provides smooth feeding but still maintain high stiffness.

- Vertical spindle Y axis uses peumatic counterweigh to reduce ball screw and servo motor loading to make movement more smoothly and extend the use of life.

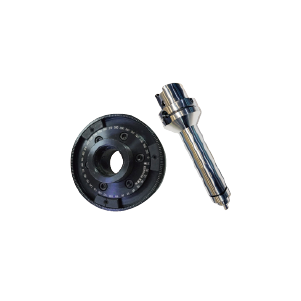

- Horizontal Spindle uses six high precision ball bearings for heavy grinding.

Specification

| Description | VHR-600 | VHR-800 |

|

| Table size | 600mm | 800mm | |

| Processing travel (vertical spindle) | Grinding inside diameter Grinding outside diameter | 60~550mm MAX Ø600mm | 60~650mm MAX Ø800mm |

| Table maxi grinding radius (horizontal spindle) | 320mm | 400mm | |

| Distance of table surface to spindle surface top (vertical spindle) | 850mm | 850mm | |

| Distance of table surface to spindle surface center (horizontal spindle) | 580mm | 580mm | |

| Table load (bearing type) | 350kg | 600kg | |

| Table load (hydrostatic type) | 500kg | 800kg | |

| Table speed | 250r.p.m. | 150r.p.m. | |

| Workpiece grinding height (vertical spindle) | Inside diameter Outside diameter | 350mm | 350mm 400mm |

| Workpiece grinding height (horizontal spindle) | MAX 450mm | MAX 450mm | |

| Vertical spindle horse power | HSK63 HSK100 | 17kw 20kw | - 20kw |

| Horizontal spindle horse power | 7.5kw | 7.5kw | |

| Vertical spindle speed | HSK63 HSK100 | 2000~12000r.p.m. 2000~10000r.p.m. | - 2000~10000r.p.m. |

| Horizontal spindle speed | MAX 2000mm | MAX 2000mm | |

| Wheel size | Vertical spindle Horizontal spindle | 50~255mm 355x38x127mm | 50~255mm 405x50x127mm |

| Turret | 6T | 6T | |

| Net weight/gross weight (approx.) | 18000/20000kg | 20000/22000kg |

※ The manufacturer reserves right to modify the design , specification mechanisms etc. without notice.

Workpiece Sample